Panels - Birch Plywood

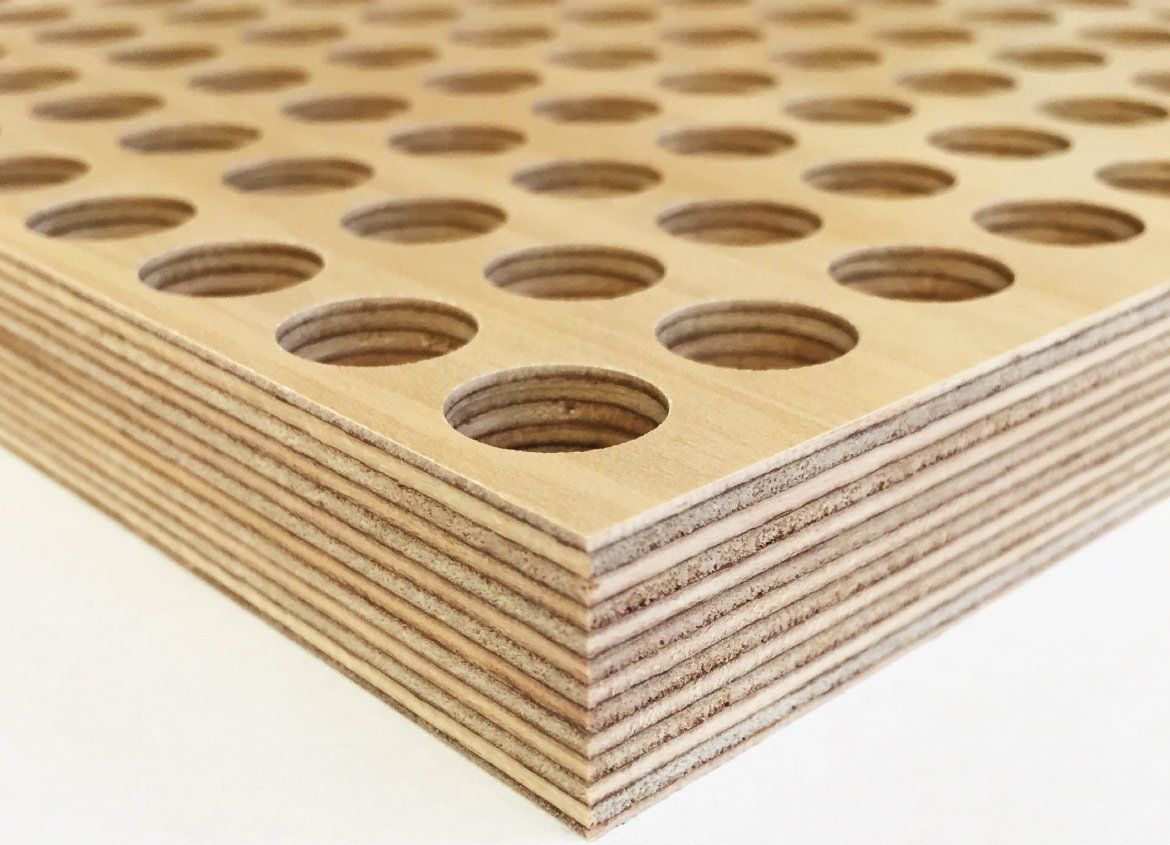

European birch throughout plywood. Each veneer in the panel is of a high quality and produced to an environmentally friendly standard.

Our Birch Plywood Page has more details on face grading rules. E grade is a special plug free face.

European birch throughout plywood. Each veneer in the panel is of a high quality and produced to an environmentally friendly standard.

Face grade: E, B or BB

Produced to EN363-3 Classes: E, B or BB, with a repaired and repurposed BB grade reverse.

Our Birch Plywood Page has more details on face grading rules. E grade is a special plug free face.

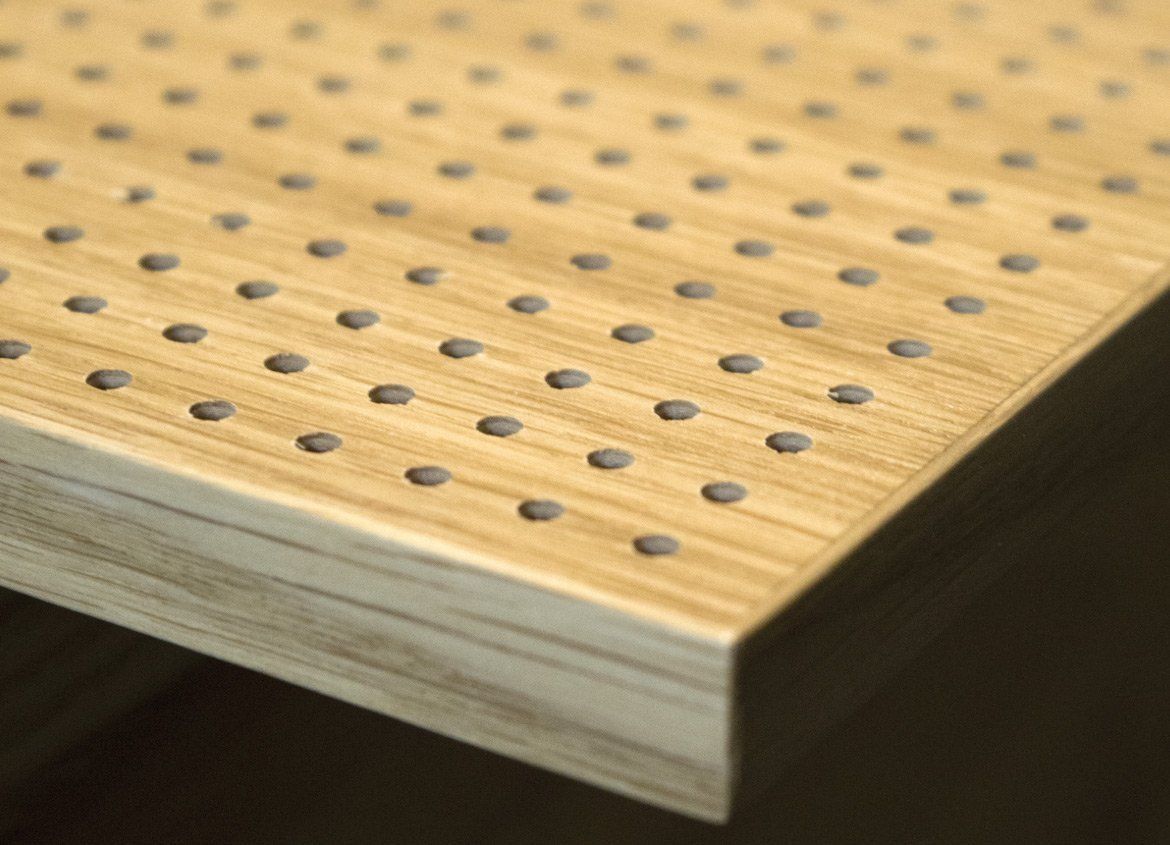

Panels - Veneered

American White Oak

Character Oak

European Oak

Ash

Cherry

Black Walnut

Maple

Crown Sapele

Steamed Beech

White Beech

Wenge

American White Oak

Character Oak

European Oak

Ash

Cherry

Black Walnut

Maple

Crown Sapele

Steamed Beech

White Beech

Wenge

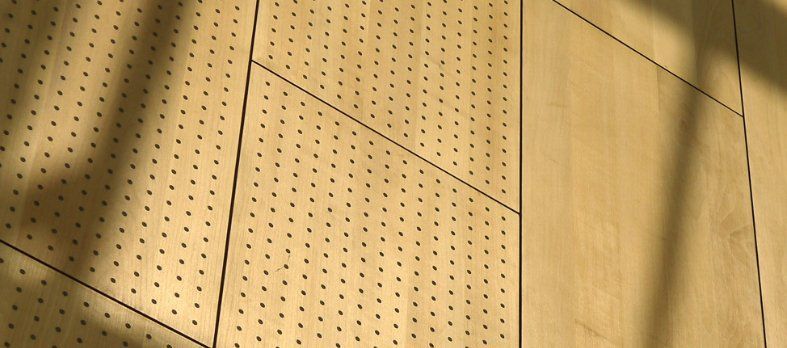

UK finished by our expert veneering factory, each of our veneer options are carefully selected to meet customer requirements. Our standard range is tailored for projects needing consistent colour, grain and matching selection whilst remaining a cost-effective option.

Our bespoke range suits client with ambitious and extravagant requirements. From original concept to final production, we will ensure all parties are happy and expectations are exceeded. Popular Applications: Lecture Theatres, Hotel Lobby and Reception, Meeting Rooms, Offices

Panels - Melamine & Laminates

Available in a very wide range of patterns, effects and colours.

Wood grain laminates may be an option where no visual variations are permitted and general consistency is important.

Plywood or MDF can be bonded with laminates or pressed with melamine faces. Ideal for when consistency is important, such as colour matching various elements or themes of the overall build. Laminates in particular are robust and ideal for high traffic or demanding areas.

Wood grain laminates may be an option where no visual variations are permitted and general consistency is important.

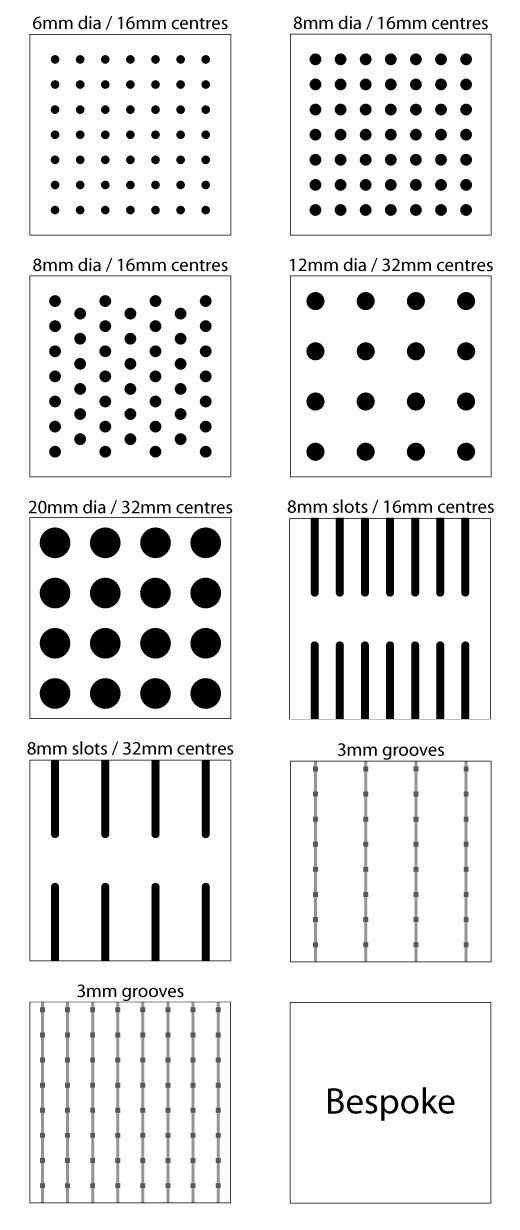

Patterns

Our standard patterns are shown below - plus we offer bespoke designs

Our standard patterns are shown below - plus we offer bespoke designs

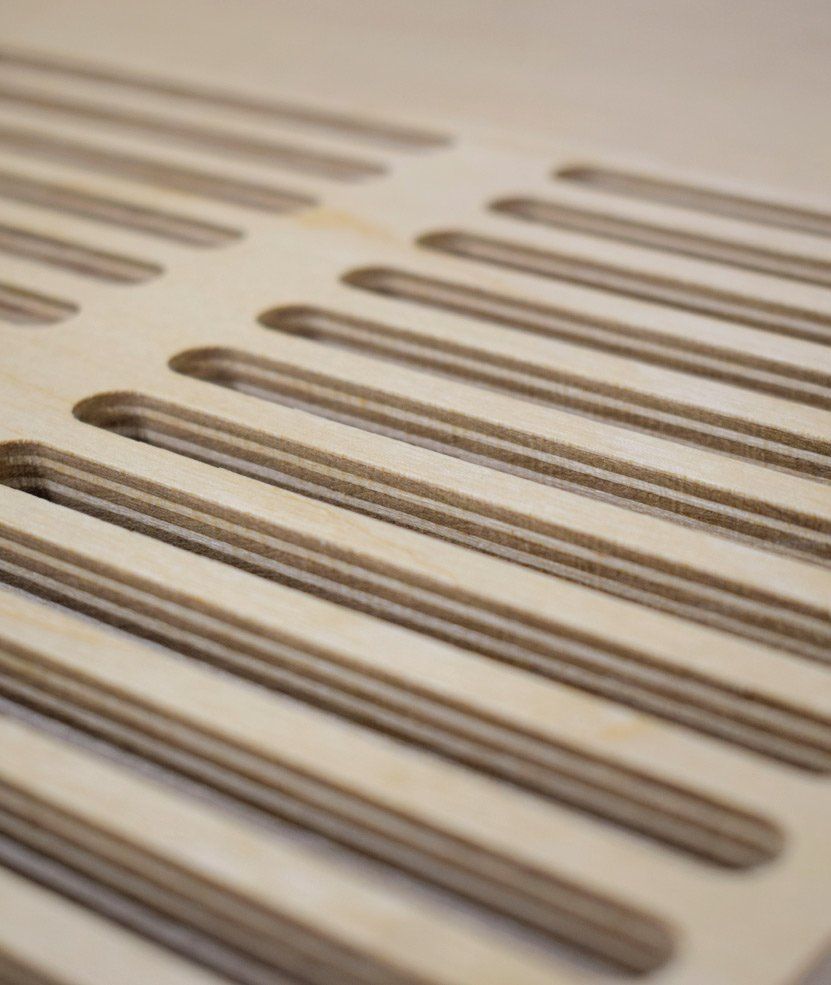

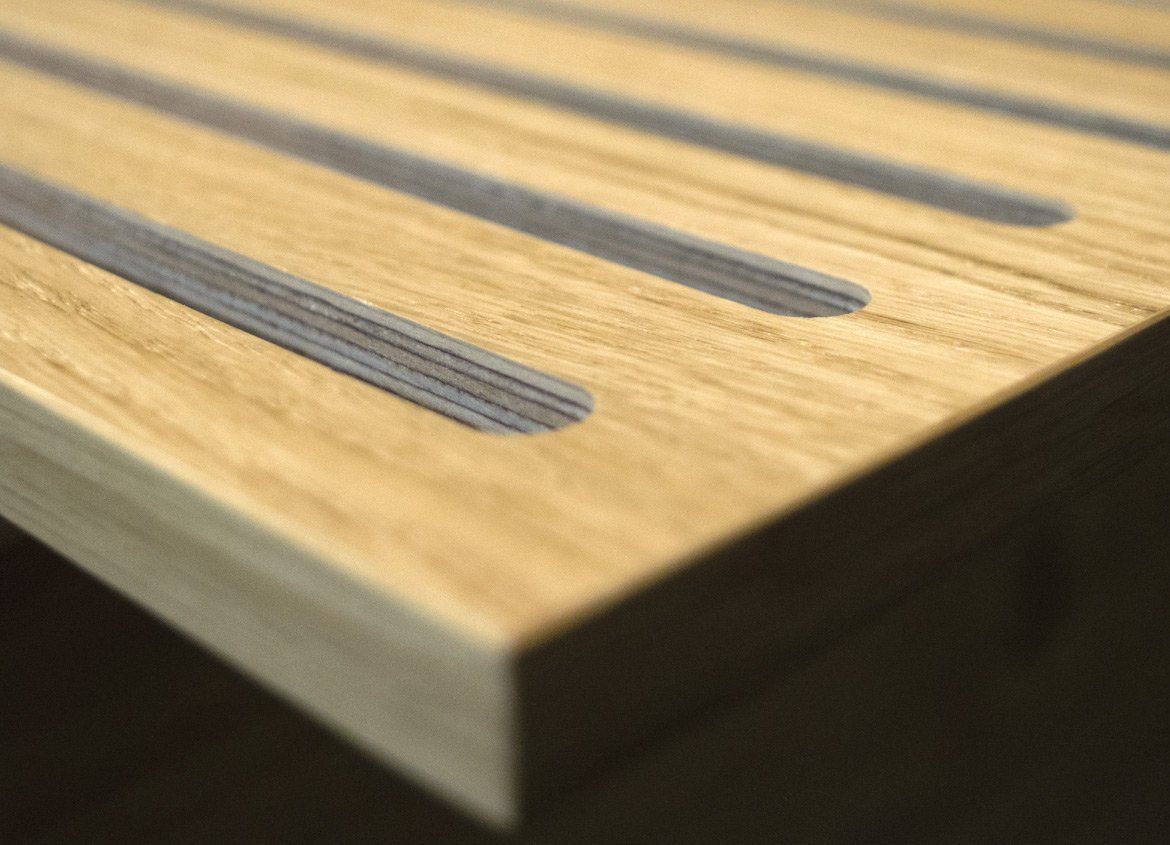

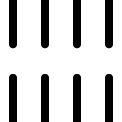

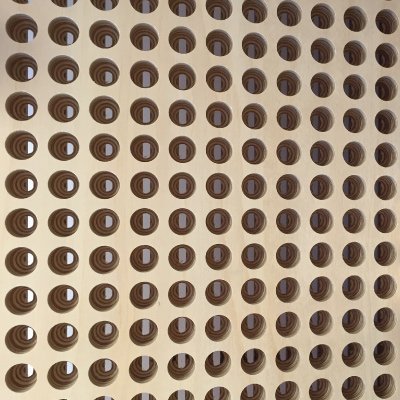

Grooved & Perforated

The front face is grooved at 3mm wide

The reverse is partially drilled

Finishes

Painted Any RAL number

Dulux references

Colour matching service

UV hardened Lacquer Matt or gloss high strength lacquer provides a tactile finish to enhance and protect the panel.

Burnblock Lacquer

is ultra matt with a natural touch. This maintains the EN13501-1 fire rated standard that is often required in most new projects.

Painted Any RAL number

Dulux references

Colour matching service

Edge Detail

Loose Tongue & Groove

Chamfered

Painted / lacquered

Loose Tongue & Groove

Chamfered

Painted / lacquered

Acoustic Fleece

A black viscose / polyester sheet bonded to the panel reverse.

180 microns, weighing 50g/m2

Flame retarding class B1

Fibre-glass free

A black viscose / polyester sheet bonded to the panel reverse.

180 microns, weighing 50g/m2

Flame retarding class B1

Fibre-glass free

Solid Panels

We can supply plain panels to compliment and contrast the acoustic panels.

These panels will be the same production as the perforated panels and undergo the same finishing process to ensure consistency of colour, sheen and texture.

On larger scale projects, we can offer contrasting solid panels to provide a visual break. This could be melamine, veneered or painted finishes.

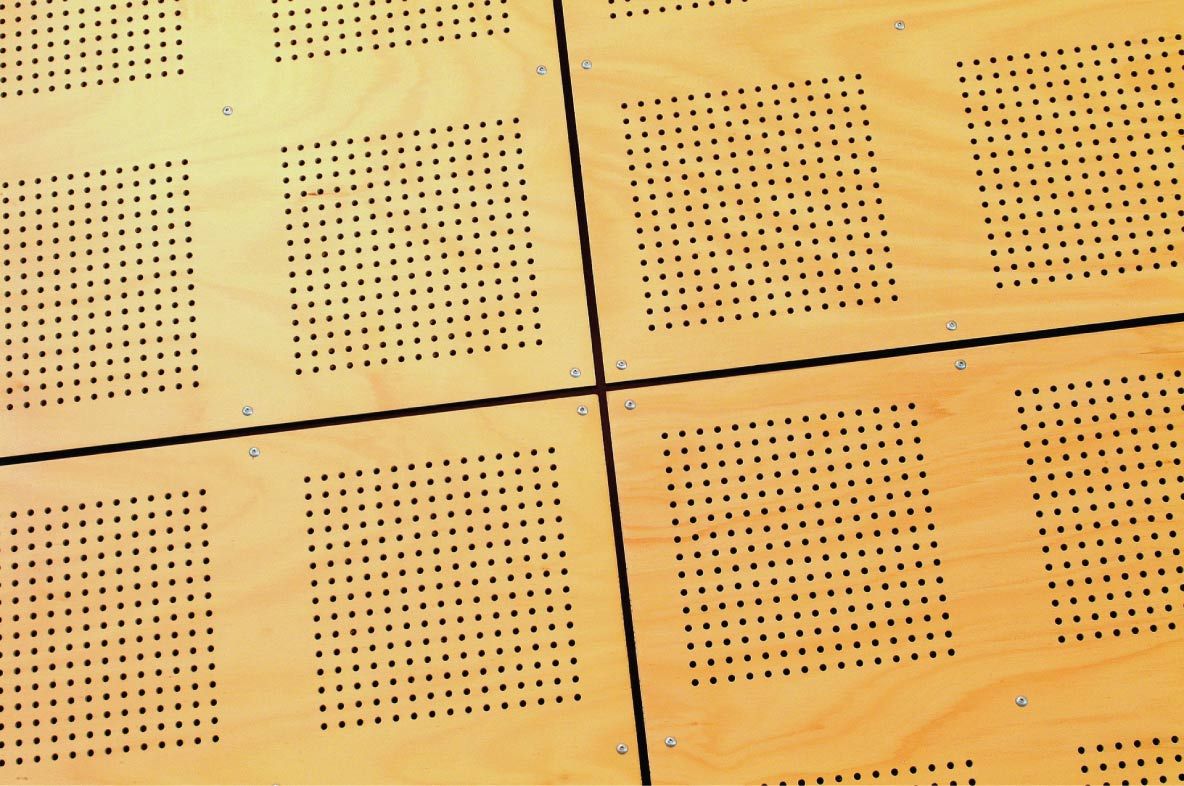

Face Fixing

Pinning - Using a lost head nail to secure directly into supporting studwork behind at 300mm centres across all areas of the panels. This method provides a clearer face and a permanent fixing method.

Screws

- Using a stainless steel screw and washer on the border edge of the panels at 300mm centres (24 fixings on outer border). This method makes a feature of the fixing and ideal if panels need removing to access ME services.

Secret Fixings - Split Battens

- Timber 40-45mm thick. Standard construction CE marked timbers are generally used working to industry standard timber subframe requirements.

- Extruded Aluminium 5.5mm-9.5mm aluminium Goodings split battens. A heavy-duty and robust split batten ideal for sports hall or heavy traffic areas where an accessible panel is required.

- Machined Plywood 18mm thick Burnblock treated plywood. Best of both worlds: thin and strong, but lightweight and eco-friendly.

Standards

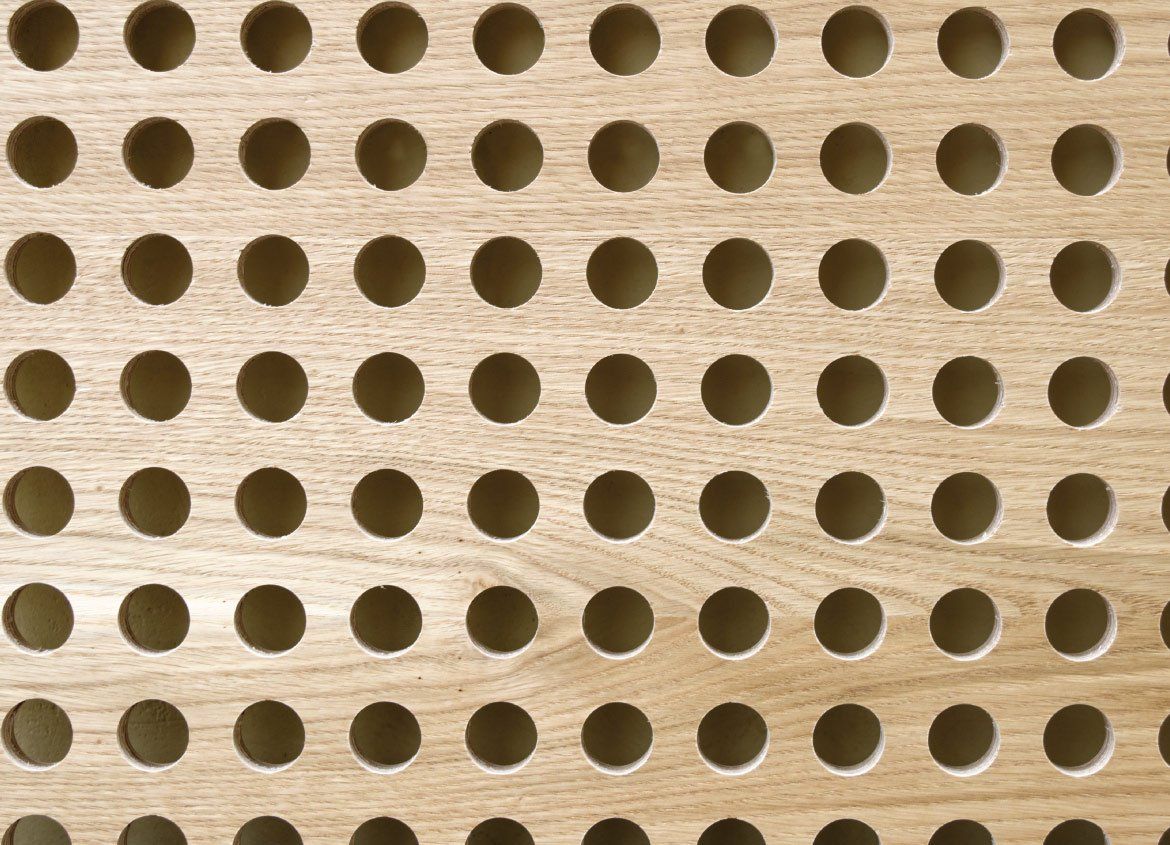

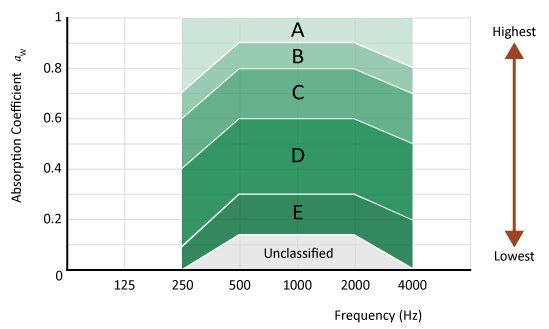

The material’s ability to absorb sound is generally presented with absorption coefficients measured in different frequencies. This means in practice that one material has a number of different absorption coefficients based on frequencies.

When specifying a suitable absorption class for each product, a product is first measured according to EN ISO 354:2003. The result from this test is an absorption curve, which declares absorption coefficients for each frequency used in the test.

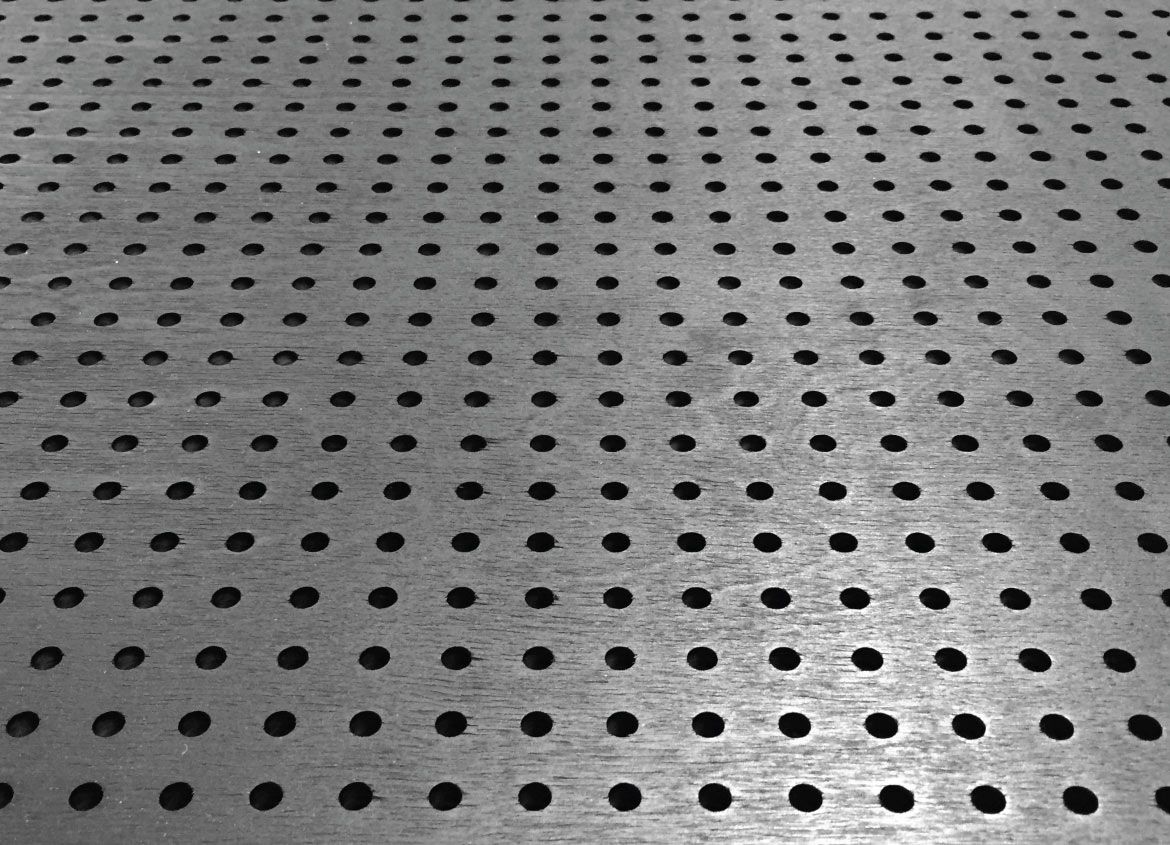

Independently tested standard perforations to meet BS 8233:2014. We work with clients, architects and designers to achieve the acoustic rating and visual aesthetics required for the project.

Acoustic absorption is achieved by sound waves passing through the open area in our panels and baffled by the acoustic fleece behind. Our standard range of machining achieves a high Class C rating (with potential for a higher rating using bespoke machining or additional insulation behind the panels)

ISO 11654:1997 Acoustics – Sound absorbers for use in buildings – Rating of sound absorption

Testing terminology - BS EN ISO 354:2003Acoustics. Measurement of sound absorption in a reverberation roomThe material’s ability to absorb sound is generally presented with absorption coefficients measured in different frequencies. This means in practice that one material has a number of different absorption coefficients based on frequencies.

When specifying a suitable absorption class for each product, a product is first measured according to EN ISO 354:2003. The result from this test is an absorption curve, which declares absorption coefficients for each frequency used in the test.

Architect & Contractor Assistance

Fixing advice - We can work with sub-contractors / fit-out companies to assist with installation

Packing options - Packed in order of installation sequence to help with project scheduling

Panel identification - Numbered as per your elevations for easy installation

Veneer matching - Numbered and identified to achieve the desired veneer matching sequence

Delivery - Various services: FORS, Moffit, Hiab, Artic, Rigid and dedicated vehicles

Installation - We supply panels only, but have a network of experienced and trusted independent installers to recommend

Project Presentations- We can provide on-site presentations and discussion/brain-storming service to advise on budgets, timescales, project requirements and solutions.

NBS/RIBA Specification- Assistance on specification details

Planning and specifying - Draw on our broad knowledge of panel products & timber

Drawing take-off - We work with calculations, take-offs and drawing elevationsFixing advice - We can work with sub-contractors / fit-out companies to assist with installation

Packing options - Packed in order of installation sequence to help with project scheduling

Panel identification - Numbered as per your elevations for easy installation

Veneer matching - Numbered and identified to achieve the desired veneer matching sequence

Delivery - Various services: FORS, Moffit, Hiab, Artic, Rigid and dedicated vehicles

Installation - We supply panels only, but have a network of experienced and trusted independent installers to recommend

Contact us for a quote

As importers, we are set up to deal in commercial volumes to companies